|

Sectores de aplicación de los sensores de Senceive y Omnidots

|

Auscultación vía ferrea

Auscultación de superestructura o vía; peralte, alaveo y perfil longitudinal. Monitoreo de infraestructura. Convergencias, deformaciones y subsidencias en túneles y puentes |

|

Monitorización de taludes

Alerta temprana de movimientos y desprendimientos |

|

Auscultación de puentes

Monitoreo y auscultación de puentes |

|

Geotecnia

Excavaciones profundas, auscultación y monitoreo, movimientos del suelo y subsuelo, automatización de instrumentación geotécnica; inclinómetros, IPI, piezómetros, células de carga, extensómetros |

|

Patrimonio

Monitorización obra de fábrica para predicción y mantenimiento de edificios y estructuras |

|

Ingeniería civil

Auscultación y monitorización de estructuras, puentes, túneles, pantallas, muros, vuelcos, convergencias, perfiles longitudinales y verticales, cargas, tensiones, pruebas de carga |

|

Infraestructuras especiales

Auscultación de superestructura o vía; peralte, alaveo y perfil longitudinal. Monitoreo de infraestructura. Convergencias, deformaciones y subsidencias en túneles y puentes |

|

Auscultación en topografía

Las nuevas oportunidades del topógrafo en la auscultación y monitorización por sensores |

|

Energía

Monitoreo y auscultación de presas, oleoductos, parques eólicos, chimeneas, estabilidad, deformaciones, presión, tensión, pruebas de carga |

|

|

|

Estaciones totales Leica

Estaciones totales Leica Estaciones totales manuales FlexLine

Estaciones totales manuales FlexLine Estaciones totales robotizadas

Estaciones totales robotizadas Estaciones totales robotizadas TS13

Estaciones totales robotizadas TS13 Estaciones totales robotizadas TS16

Estaciones totales robotizadas TS16 Multiestación Leica MS60

Multiestación Leica MS60 HP SitePrint

HP SitePrint Controladoras

Controladoras Jalones Ap20

Jalones Ap20 Estaciones Leica iCON

Estaciones Leica iCON Leica CCP

Leica CCP GPS Leica

GPS Leica Receptores

Receptores GIS Leica

GIS Leica HxGN SmartNet

HxGN SmartNet iCON trades

iCON trades Guía Escáneres Láser BLK

Guía Escáneres Láser BLK Leica Pegasus - reality capture

Leica Pegasus - reality capture RTC360

RTC360 Leica BLK360 G2

Leica BLK360 G2 BLK2GO

BLK2GO BLK2GO Pulse

BLK2GO Pulse Mobile Mapping

Mobile Mapping Pegasus TRK100

Pegasus TRK100 Accesorios 3D

Accesorios 3D Leica Disto

Leica Disto Disto D5

Disto D5 Disto X3

Disto X3 Disto X6

Disto X6 Disto S910

Disto S910 Lino P5-1

Lino P5-1 Lino L2S-1

Lino L2S-1 Lino L6R

Lino L6R Lino L4P1

Lino L4P1 Accesorios Disto

Accesorios Disto Intro Auscultación

Intro Auscultación SENCEIVE

SENCEIVE OMNIDOTS Sensores de Vibracion

OMNIDOTS Sensores de Vibracion SWARM Sound sonómetro

SWARM Sound sonómetro Auscultación Leica

Auscultación Leica Casos de estudio

Casos de estudio Aplicaciones y sectores

Aplicaciones y sectores Niveles Leica

Niveles Leica Láser de línea Leica Lino

Láser de línea Leica Lino Niveles láser Leica

Niveles láser Leica Niveles láser Nedo

Niveles láser Nedo Niveles digitales LS

Niveles digitales LS Niveles ópticos

Niveles ópticos Nivel Piper 100/200

Nivel Piper 100/200 Inclinómetros

Inclinómetros SEGURIDAD iCON

SEGURIDAD iCON Excavadora

Excavadora Grader - motoniveladora

Grader - motoniveladora Dozer

Dozer Compactadoras

Compactadoras Pala cargadora

Pala cargadora Incadoras

Incadoras Perforadoras

Perforadoras Receptores Láser de maquinaria

Receptores Láser de maquinaria DJI Mavic 3

DJI Mavic 3 DJI Matrice

DJI Matrice DJI Agras

DJI Agras Drones Leica

Drones Leica Accesorios drone

Accesorios drone FlyFire

FlyFire Software

Software Software MDT Aplitop

Software MDT Aplitop Guía Ferroviario

Guía Ferroviario Amberg carros de via

Amberg carros de via Productos CARTTOP

Productos CARTTOP Accesorios Ferroviario

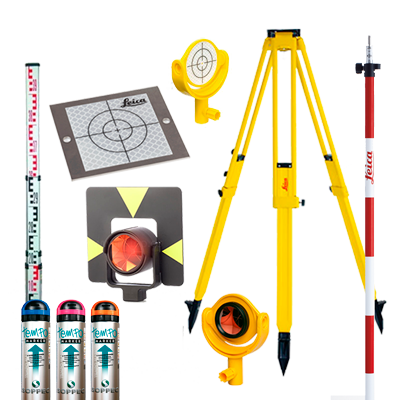

Accesorios Ferroviario Accesorios Estaciones Totales

Accesorios Estaciones Totales Accesorios GPS

Accesorios GPS Accesorios Láser Escáner 3D

Accesorios Láser Escáner 3D Accesorios niveles láser

Accesorios niveles láser Accesorios niveles ópticos y digitales

Accesorios niveles ópticos y digitales Accesorios varios

Accesorios varios Trípodes topografía

Trípodes topografía Jalones

Jalones Bases Nivelantes

Bases Nivelantes Baterías y cargadores

Baterías y cargadores Miras

Miras Piezas Instop

Piezas Instop Prismas y dianas

Prismas y dianas Radioteléfono

Radioteléfono Adaptadores y convertidores

Adaptadores y convertidores Aerosoles, spray obra

Aerosoles, spray obra Estacas

Estacas Dianas

Dianas Clavos y Arandelas

Clavos y Arandelas Fisurómetros

Fisurómetros Hitos

Hitos Marcadores

Marcadores Soportes y cartelas

Soportes y cartelas Detección de Cables

Detección de Cables Georadar Leica DS2000

Georadar Leica DS2000 Leica DSX

Leica DSX IDS GeoRadar

IDS GeoRadar C-THRUE-XS

C-THRUE-XS C-THRUE

C-THRUE  Stream DP 30 canales

Stream DP 30 canales

SU COMPRA

SU COMPRA